HOT PRODUCTS

epoxy resin+ filler made of coal tar pitch anti-corrosive coating on steel surface coated glass fabric as reinforcement anti-corrosion layer formation, commonly used in the pipe wall corrosion thickness of 0.5-1.0mm Size OD :20-3600mm Thickness :1-80mm Length :Random Length,Fixed Length,SRL.DRL Standard :API 5L/ASTM A53-2007/ASTM A106-2006/BS1139/BS1387 Material: ChineseGrade Q215,0235,10# 20# according to GB/1700;Q345 According to GB71591 Foreign Grade ASTM ...

the steel surface electrostatic spraying, epoxy powder and binder twine lateral wound polyethylene coating, combined with three excellent performances, thereby significantly improving the overall quality of anti-corrosion of the pipe. The coating is made of hot-melt epoxy powder (FBE) as the bottom layer (2LPE/PP epoxy powder without bottom layer), ethylene/propylene copolymer cavity adhesive (AD) as the middle layer, and high-density polyethylene(PE)/propylene

epoxy resin+ filler made of coal tar pitch anti-corrosive coating on steel surface coated glass fabric as reinforcement anti-corrosion layer formation, commonly used in the pipe wall corrosion thickness of 0.5-1.0mm Size OD :20-3600mm Thickness :1-80mm Length :Random Length,Fixed Length,SRL.DRL Standard :API 5L/ASTM A53-2007/ASTM A106-2006/BS1139/BS1387 Material: ChineseGrade Q215,0235,10# 20# according to GB/1700;Q345 According to GB71591 Foreign Grade ASTM ...

epoxy resin+ filler made of coal tar pitch anti-corrosive coating on steel surface coated glass fabric as reinforcement anti-corrosion layer formation, commonly used in the pipe wall corrosion thickness of 0.5-1.0mm Size OD :20-3600mm Thickness :1-80mm Length :Random Length,Fixed Length,SRL.DRL Standard :API 5L/ASTM A53-2007/ASTM A106-2006/BS1139/BS1387 Material: ChineseGrade Q215,0235,10# 20# according to GB/1700;Q345 According to GB71591 Foreign Grade ASTM ...

Why Choose R·STEEL?

We are in possession of 10,000 tons, 6,000 tons, 4,000 tons, 3,600 tons full scales large JCOE forming production lines, and 200mm, 180mm, 150mm, 130mm, 100mm thickness heavy three-rollers bending machines, complete anti-corrosion painting facility. The annual SAW pipes capacity comes to 300,000 tons.

9/5000 Company established in 2008

Comprehensive production capacity of 300000 tons

More than 200 test items

Factory

Factory

Factory

Factory

PRODUCTION STRENGTH

Achieving quality requires technique, and achieving brilliance requires technology.

Innovative Ideas

Jiangyin Ronggang Pipeline Manufacturing Co., Ltd. has always maintained a commitment to innovation and development that has led to the introduction of three reeling pipe production lines, one longitudinal submerged arc welding pipe production line;

Annual output of ten thousand tons

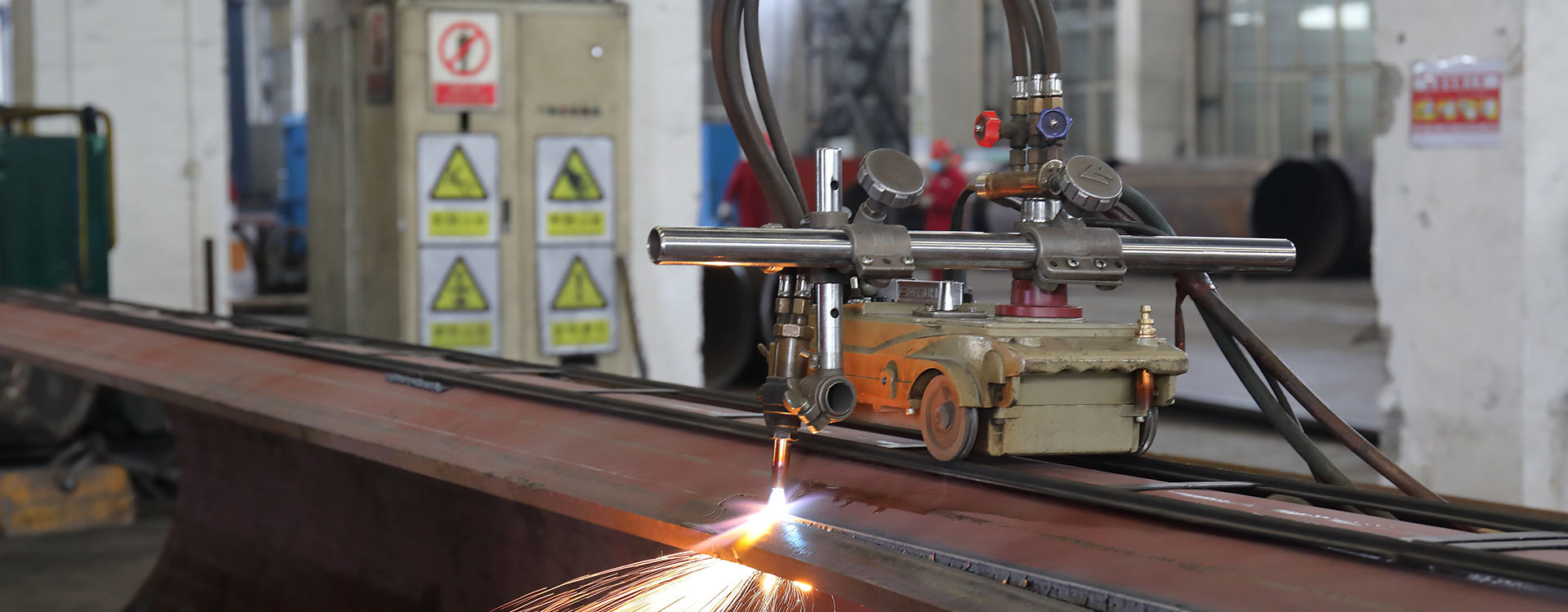

As well as support facilities such as paint anti corrosion, intersecting line cutting and processing, achieving an annual comprehensive production capacity of 100,000 tons.

Advanced supporting equipment

With modern corollary equipment, mature production technology, and a stringent quality control system, the firm has built a diverse product system, including various specifications of SAWL pipes, special-shaped pipes, and steel structures, among others.